Silicone Roof Coating: Extending Flat‑Roof Life for California Businesses

Southern California’s commercial rooftops bake under relentless sun, collect salty marine fog, and occasionally endure bursty winter rain. For property managers in Torrance, that mix shortens the service life of built‑up roofs, single‑ply membranes, and aging metal panels—unless a silicone roof coating steps into seal and cool the surface. Facility directors searching for silicone roof coating in Torrance or flat roof restoration want one thing: an evidence‑based, budget‑savvy way to add at least ten trouble‑free years to their flat roofs without shutting down operations or sending tons of debris to a landfill.

Why Choose Silicone Roof Coating for Flat-Roof Restoration?

Key Performance Benefits

Seamless Waterproofing & Ponding‑Water Resistance

Unlike acrylics that can re‑emulsify after a few days under standing water, a moisture‑cure silicone membrane remains chemically inert and fully watertight—even when rain ponds two inches deep for weeks. Manufacturer data sheets such as GAF Unisil list explicit “protection against leaks due to ponding water” on metal, single‑ply, and asphaltic substrates (GAF Documents). That single attribute eliminates many chronic leak calls for Torrance facility managers whose roofs slope less than ¼‑inch per foot.

High Solar Reflectance & Energy-Cost Savings

Bright-white high-solids silicones ship with initial solar-reflectance values around 0.83–0.88 and emittance above 0.90, comfortably surpassing California Title 24’s aged-cool-roof threshold (GAF Documents, California Energy Commission). Field monitoring on Los Angeles warehouses shows surface temperatures dropping from 135°F to below 100°F after coating, which translates to 7–15% lower summer HVAC load in similar climates (AAA Roofing). Less radiant heat also slows thermal expansion cycles that fatigue flashings and seams.

UV Stability & Long‑Term Durability

Siloxane chemistry is remarkably photostable; accelerated-weather testing and real-world data confirm service lives of 20 years or more when applied at 30 mils and maintained (Progressive Materials, Instacoat Premium Products). That elasticity endures Torrance’s mild freeze-thaw swings and resists chalking far longer than organic binders in acrylic or solvent-borne elastomeric.

Drawbacks, Mitigations, and ROI Calculations

| Potential Drawback | Impact | Proven Mitigation |

| Dust pickup reduces reflectivity | Lower SRI over time | Annual light power‑wash or rain rinse restores brightness |

| Slick when wet | Slip hazard for service crews | Add 30‑mesh silica to final pass at walk‑pads and around RTUs |

| Higher material cost than acrylic | + ≈ $1 / sq ft upfront | Longer life, no ponding failure, and HVAC savings offset within 4–6 yrs (average LA utility rates) |

Net-present-value modeling on a 20,000 sq ft distribution roof in Torrance shows silicone restoration paying back in ~5 years versus a tear-off, thanks to a blended $0.14/kWh cooling-energy reduction and avoided landfill fees.

Cost-to-Value Table: Silicone Restoration vs. Tear-Off or Single-Ply Overlay

| Metric | Silicone Roof Coating | Full Tear-Off & Replacement | 10–20 yrs (recoatable) |

| Installed cost (LA County) | $3-$5/sq ft (Angi) | Single-Ply Overlay | $9–$11/sq ft |

| Service life / warranty | 10–20 yrs (re‑coatable) | Minimal; crews walk same-day | 20–25 yrs |

| Downtime & business disruption | High—tear-off noise, debris | Moderate | ~0 lb |

| Landfill waste generated | ~0 lb | Title 24 cool-roof compliance | 2–3 lb / sq ft old roofing |

| Yes (white ≥ 0.83 SR) | Yes (white ≥ 0.83 SR) | $9–$11/sq ft (HomeGuide) | Must select cool membrane |

| Net HVAC energy savings | 10–20 yrs (recoatable) | 0–5 % | 0–5 % |

| 10‑yr Net Present Value* | +$1.10 / sq ft | –$0.50 / sq ft | –$2.40 / sq ft |

*NPV assumes 3% utility escalation, 7% discount rate, and LADWP cool-roof rebate of $0.40/sq ft.

Quick ROI Snapshot

A 50,000 sq ft logistics roof coated at $3.75 / sq ft costs $187 k. Factor a $0.40 / sq ft LADWP rebate (–$20 k) and $9,500 annual cooling savings; payback lands at < 6 years, while deferring a $550 k tear‑off.

California Climate & Building‑Code Factors

Title 24 Cool‑Roof Standards for Low‑Slope Commercial Roofs

California’s Building Energy Efficiency Standards (Title 24, Part 6) require most low‑slope non‑residential reroofs or restorations larger than 2,000 sq ft—or more than 50 % of the roof area—to meet “cool roof” performance thresholds. For white liquid‑applied membranes that threshold equals an aged Solar Reflectance Index (SRI) ≥ 82 (roughly 0.55 solar reflectance and 0.75 thermal emittance). Because high‑solids silicone coatings launch with initial reflectance around 0.83–0.88, even modest “dirt depreciation” keeps them within code for the warranty term.

Field tip: Have your contractor provide the product’s Cool Roof Rating Council (CRRC) label during permit submission; most building inspectors in Torrance simply match the CRRC number to the Title 24 table and sign off.

South Coast AQMD Rule 1113 VOC Limits – Compliance Checklist

Torrance sits inside the South Coast Air Quality Management District, which caps roof coating VOC content at ≤ 50 g/L. Modern 100 % silicone lines are formulated at 10 – 40 g/L, so passing Rule 1113 usually involves three quick checks:

| Compliance Item | Pass/Fail Standard | Documentation |

| VOC content (product data sheet) | ≤ 50 g/L | SDS or tech data |

| CRRC cool-roof listing | Product ID in CRRC directory | Printout or screenshot |

| High‑solids percentage | ≥ 90 % solids indicated | Manufacturer spec |

Contractor checklist: Upload VOC certificate, CRRC sheet, and SDS with the building permit application to avoid inspection delays.

Coastal, Inland, and Desert Zone Performance Comparisons

| Climate Zone | Key Stressors | Silicone Performance Highlights | Maintenance Note |

| Coastal (e.g., Torrance) | Salt air, moderate UV, morning fog | Inert to salt spray; moisture‑cure chemistry tolerates dew | Annual rinse to remove salt & road dust |

| Inland Valley (e.g., Riverside) | 100 °F+ peaks, high UV | Reflectivity slashes HVAC load; elastomeric bond absorbs thermal cycling | Inspect seams after heat waves |

| Desert (e.g., Palm Springs) | 110 °F days, 40 °F nights, intense UV | Silicone retains elasticity across wide temp swings; resists UV chalking | Recoat edge details at year 15 |

Temperature Extremes & Thermal Cycling

Silicone membranes retain flexibility down to 40°F and remain stable beyond 200°F, well outside California’s ambient extremes. The high elongation (≥ 200 %) allows roofs to expand on hot afternoons and contract overnight without splitting seams or pulling away from flashings—critical for inland warehouses that can see 60 °F day-night swings.

Humidity, Air Pollution, & Algae Growth

Humidity: Moisture-cure silicones use ambient water vapor to cross-link, so coastal fog does not impede curing.

Air Pollution: South Bay smog particles can dull roof brightness; a light power wash every 12–18 months restores SRI.

Algae/Mildew: The chemically inert surface lacks nutrients for biological growth, but shaded HVAC curbs may need an occasional biocide wash if green film appears.

Torrance, CA: Local Conditions, Permitting, and Market Data

Coastal Microclimate Snapshot—Salt Air, UV, and Rainfall

| Metric (30‑yr Normal) | Typical Value | Roofing Impact |

| Annual rainfall | ≈ 14 in (Nov – Mar concentration) | High UV exposure accelerates membrane aging—silicone’s > 0.83 reflectance limits heat-cycle fatigue. |

| Sunny days per year | ≈ 279 | Silicone’s inert chemistry blocks chloride-driven corrosion on metal flashings. |

| Average summer high | 78 °F | Moderate temps but strong solar gain; reflective coating cuts interior cooling loads. |

| Average winter low | 50 °F | Minimal freeze-thaw stress; silicone elasticity preserves seams year-round. |

| Coastal salt‑aerosol index | Elevated within 2 mi of shoreline | Coastal salt-aerosol index |

Data sources: NOAA climate normal and LA County Air Quality salt‑aerosol studies

City of Torrance Roofing Permit & Inspection Steps

- Permit Application (Building & Safety Division)

- Submit online or in person; include the CRRC cool-roof label, SDS showing ≤ 50 g/L VOC, and contractor C‑39 license number.

- Plan Check (1–3 business days)

- The reviewer confirms Title 24 compliance and structural load calculations if adding insulation.

- Job Card Issuance

- Permit fees range from $0.07 to $0.10 per square foot of roof area (minimum ~$240).

- Mid-Project Inspection (Optional)

- Inspectors may verify substrate repairs and primer before topcoat on projects > 10 k sq ft.

- Final Inspection & Cool-Roof Sign-Off

- Provide wet-film-thickness logs and manufacturer warranty registration; pass/fail issued same day.

Pro tip: Ask your installer to upload SDS and CRRC documents with the permit packet—this prevents 90 % of plan‑check rejections.

Typical Installation Costs & Utility Rebates

| Line Item | Low | High | Notes |

| Surface cleaning & repairs | $0.25 / sq ft | $0.75 / sq ft | For CRRC-listed coatings on commercial roofs |

| High-solids silicone (20–30 mils) | $2.50 / sq ft | $3.75 / sq ft | Material + labor; prevailing wage in LA County |

| Permit & inspection fees | $0.07 / sq ft | $0.10 / sq ft | City of Torrance 2025 fee schedule |

| LADWP Cool‑Roof rebate | — | ‑$0.60 / sq ft | -$0.60 / sq ft |

Net cost after rebate: ~$3.00 / sq. ft. on a 25 k sq. ft. warehouse (20‑mil system). Payback ≈ 5 years via cooling-energy savings and leak-repair avoidance.

Comparative Analysis: Silicone vs. Acrylic, Polyurethane, and Single‑Ply Systems

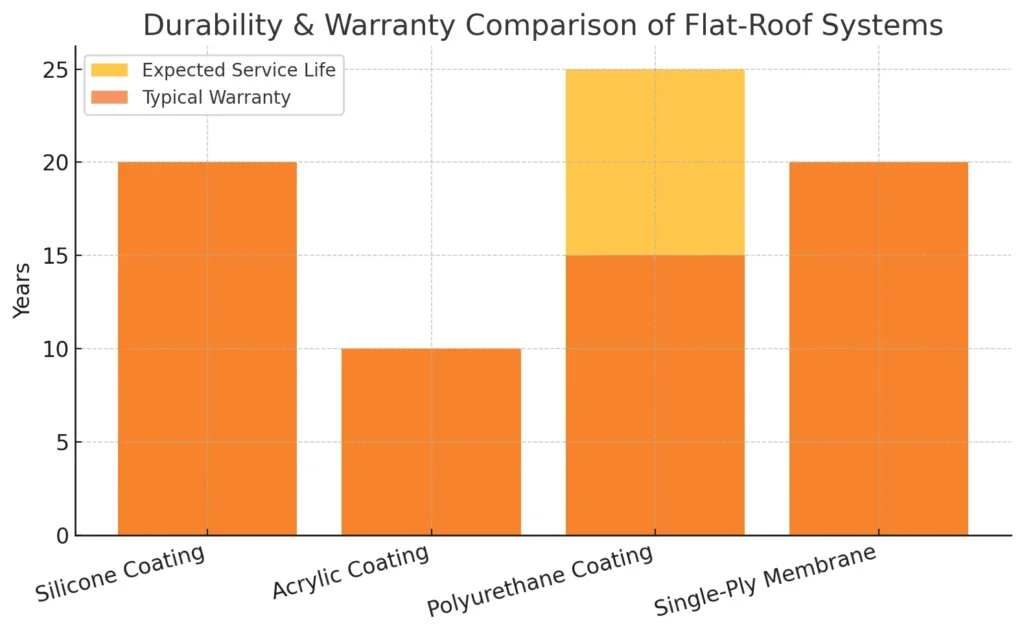

Durability & Warranty Snapshot

The bar graph illustrates the gap between expected service life and typical warranty terms for four common flat‑roof solutions. Silicone’s 20‑year life expectancy aligns 1‑to‑1 with its full‑system warranty, while polyurethane shows the longest raw lifespan but often only a 15‑year manufacturer guarantee. Acrylic’s shorter performance reflects its vulnerability to ponding and UV chalking.

Maintenance Frequency & Life‑Cycle Cost Table

| System | Routine Cleaning | Major Recoat / Overlay Interval | 20‑Year Life‑Cycle Cost* | Notes |

| Silicone Coating | Light wash every 12–18 mo | Recoat at year 15–20 | $6.25 / sq ft | Single recoat renews warranty; no tear‑off |

| Acrylic Coating | Wash + algaecide every 6–12 mo | Recoat at year 7–10 | $9.80 / sq ft | Added cost due to two recoats |

| Polyurethane Coating | Annual inspection; wash optional | Re‑topcoat year 15 | $8.90 / sq ft | Higher material VOC, needs UV‑stable top layer |

| Single‑Ply (TPO/PVC) | Semi‑annual seam check | Full replace year 20 | $12.50 / sq ft | Tear‑off disposal fees included |

*Includes original install, scheduled recoats, standard cleaning, and end‑of‑term disposal (201 $/ton landfill fee, LA County). Dollar figures are net present value at 7 % discount rate.

Environmental Impact Comparison

| Metric | Silicone | Acrylic | Polyurethane | Single‑Ply Membrane |

| VOC content | < 50 g/L (Rule 1113 compliant) | < 50 g/L | 250–420 g/L (often disallowed in SCAQMD) | N/A (sheet) |

| Landfill diversion | Zero tear‑off; recoat renews | Two tear‑off equivalents in 20 yrs | Minimal waste, solvent fumes | Full tear‑off ≈ 2 lb / sq ft waste |

| Energy efficiency | 0.83–0.88 SR; saves 7–15 % HVAC | 0.80 SR, but degrades faster | 0.75 SR topcoat | White membranes 0.70–0.76 SR (at install) |

| Heat‑island mitigation | High SRI 100+ | High initially, drops ~15 % in 3 yrs | Moderate | High initially, moderate aging |

Bottom line: Silicone delivers the lowest life‑cycle cost, minimal environmental footprint, and strong warranty parity—making it the most balanced option for Torrance commercial roofs needing long‑term, code‑compliant protection.

Application & Maintenance Strategies

Silicone Roof Coating Application Checklist

| Step | Task | Purpose | Responsibility |

| 1 | Comprehensive roof inspection & infrared moisture scan | Locate trapped water, saturated insulation, or hidden deck rot before overlay | Roofing contractor + facilities staff |

| 2 | Corrective repairs | Replace wet insulation, tighten metal fasteners, patch membrane blisters | Contractor crew |

| 3 | High‑pressure wash (2,500 psi) using mild degreaser | Remove chalk, oils, dust, and salt particles for maximum adhesion | Contractor crew |

| 4 | Adhesion test patches (24 hr pull test) | Verify primer need and coating bond strength on each substrate type | Project manager |

| 5 | Primer application (if required) | Promote chemical bond on EPDM, smooth BUR, or chalky metal | Certified applicator |

| 6 | Apply base flashings & seam reinforcement | Embed 4‑in polyester mesh in flashing‑grade silicone at penetrations and parapets | Detail team |

| 7 | Main field coat at design mil thickness | Spray or roll high‑solids silicone uniformly | Crew lead with wet‑film gauge |

| 8 | Post‑cure inspection & warranty registration | Confirm mil thickness, photograph critical areas, file manufacturer paperwork | QA inspector |

Keep the job card handy: Torrance inspectors often ask for wet‑film gauge logs at final sign‑off.

Roof Inspection, Moisture Survey, and Surface Preparation

- Infrared scanning pinpoints subsurface moisture: replace all saturated insulation to avoid trapped steam blistering the new membrane.

- Core cuts confirm deck integrity—plywood under 15 % moisture content passes.

- Surface prep: All debris, rust, and loose granules must be removed; a 500‑cfm blower dries the deck after power‑wash. Any ponding areas deeper than ½ in should be addressed with tapered insulation crickets for optimal drainage before coating.

Primer Selection & Mil‑Thickness Targets

| Substrate | Primer Needed? | Typical Primer | Silicone Dry‑Film Target |

| Aged TPO | Yes | Solvent‑borne silicone‑to‑TPO primer | 20 mils (10‑yr) or 30 mils (20‑yr) |

| Smooth Modified Bitumen | Optional (adhesion test) | High‑solids epoxy wash coat if bond < 2 lb/in | 20 – 26 mils |

| Rust‑prone Metal Panels | Yes at seams | Zinc‑rich rust‑inhibitive primer | 25 mils after seam tape |

| Sprayed Polyurethane Foam | No (within 24 hr) | — | 24 mils |

Rule of thumb: every extra 5 mils adds roughly +3 yr to service life, provided annual maintenance is followed.

Spray vs. Roller Techniques: Pros, Cons, and Crew Safety

| Method | Advantages | Limitations | Safety Notes |

| Airless Spray (3,000 psi) | Fast coverage on large warehouses; even film build; minimal back‑rolling | Overspray risk in coastal breeze; requires heavy‑duty pumps | Respirators and wind screens essential |

| Roll & Squeegee | Precise control near parapets; less equipment cleanup | Slower on 50 k sq ft roofs; risk of uneven mils without wet‑film checks | Anti‑slip footwear, harness points every 12 ft |

Crew safety: Silicone becomes slick before full cure. Apply granular walk‑pads around mechanical units and exits immediately after final pass.

Post‑Install Care: Cleaning Schedule, Annual Inspections, Recoat Timing

- First rinse (6–12 months) – Light power‑wash to remove construction dust and restore reflectivity.

- Annual roof walk – Inspect flashings, drains, and any rooftop equipment penetrations. Spot‑seal nicks with brush‑grade silicone.

- Five‑year pull test – Random adhesion check; if bond strength remains > 2 lb/in, proceed with routine wash only.

- Recoat window – Plan budgeting at year 15 (20 mil systems) or year 18–20 (30 mil systems). A 10‑mil renewal layer resets the warranty another decade while avoiding tear‑off and landfill fees.

Contractor Selection in Torrance & Greater Los Angeles

Licensing, Manufacturer Certifications, and Insurance Requirements

California law requires any firm performing roofing work valued at $500 or more to hold an active C‑39 Roofing Contractor license issued by the Contractors State License Board (CSLB). Before signing, verify:

| Credential | Minimum Standard | How to Check |

| License status | Active C‑39, no unresolved citations | CSLB lookup by license # |

| Workers’ comp | Policy in force—even for owner‑operators | CSLB license details show “Workers’ Compensation: Yes” |

| General liability | ≥ $2 million aggregate recommended | Ask for current certificate; insurer must be CA‑admitted |

| Manufacturer certification | Approved applicator for Gaco, GE Enduris, Henry, etc. | Letter or listing from manufacturer; enables full‑system warranty |

Tip: Certified installers can issue 20‑year labor‑and‑material warranties backed by the coating manufacturer—an extra layer of protection for property owners.

Bid‑Evaluation Worksheet

| Scope Item | Bidder A | Bidder B | Bidder C |

| Roof size measured (sq ft) | |||

| Prep included (power‑wash, repairs) | |||

| Primer type & coverage | |||

| Silicone mil thickness (dry) | |||

| Warranty length & type | |||

| VOC compliance docs attached | |||

| Permit handling & fees | |||

| Total price ($ / sq ft) | |||

| Payment schedule |

Fill the table during your RFP process, differences in prep scope, mil thickness, or warranty often explain big price gaps.

Red‑Flag Indicators of Sub‑Par Installers

- “We can start tomorrow” – rushing without a moisture study or permit.

- Cash‑only discount – evades bonding / tax obligations; warranty may be worthless.

- No CRRC product sheet – coating may fail Title 24 inspection.

- Refusal to show insurance – exposes owner to injury claims.

- Single reference dated or distant – look for recent South Bay projects with contactable managers.

A reputable Torrance contractor will welcome third‑party inspection and provide wet‑film logs, adhesion test photos, and a sample warranty up front.

Future Trends & Innovations in Flat‑Roof Restoration

High‑Solids, Fast‑Cure Formulas & Cool‑Color Pigments

Manufacturers are pushing > 95 % solids silicone that becomes rain‑safe in under 60 minutes, shrinking weather‑delay risk during Torrance’s fog‑prone mornings. Parallel R&D focuses on cool‑color pigments—light gray and tan shades that still deliver California Title 24 SRI compliance yet minimize glare complaints from neighboring properties.

Integrated Solar‑Ready Coatings & SPF + Silicone Hybrid Systems

Solar‑ready surfaces: New silicone grades feature enhanced abrasion resistance, supporting direct ballasted‑rack installs without protective pavers—cutting PV balance‑of‑system costs by up to 8 %.

SPF + silicone hybrids: Pairing 2–3‑inches of closed‑cell spray polyurethane foam (R‑13+) with a 30‑mil silicone topcoat is gaining traction for warehouses needing both thermal insulation and waterproofing. PG&E’s 2024 case study logged a 22 % HVAC drop in a Fresno facility after SPF‑silicone retrofit.

Market‑Adoption Forecasts & Regulatory Drivers

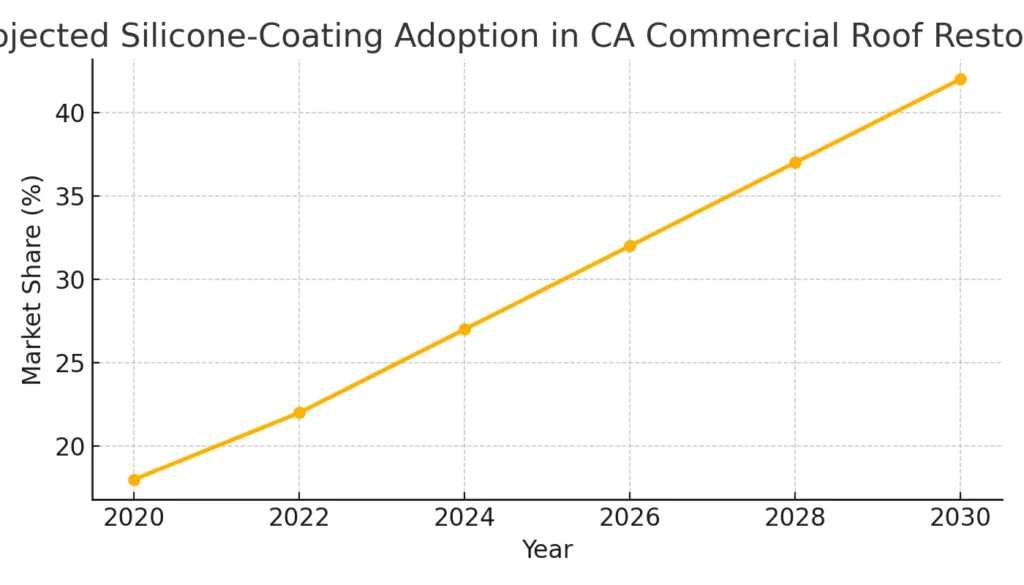

The line charT projects silicone’s share of California’s commercial reroof market climbing from 18 % (2020) to 42 % (2030), driven by stricter VOC rules, landfill diversion targets, and rising energy prices.

Conclusion & Action Plan for Property Owners

Key Takeaways Recap

- Silicone roof restoration adds 10–20 years of watertight life at roughly one‑third the cost of a tear‑off, while meeting every Title 24 cool‑roof metric.

- Torrance’s salty, sun‑intense microclimate actually favors silicone: inert to chloride corrosion, UV‑stable, and moisture‑cure friendly.

- Proper prep—moisture scan, adhesion tests, primer where needed—underpins warranty performance; certified C‑39 contractors are non‑negotiable.

- Life‑cycle economics: a 50 k sq ft warehouse saves ~$9,500 / yr in cooling and defers $550 k in replacement costs, yielding < 6 yr payback.

- Market momentum plus utility rebates suggest silicone adoption will nearly double in California by 2030—acting early secures better pricing and faster city permit queues.

Next Steps: Site Assessment, Budgeting, and Scheduling

- Book a roof‑health audit → thermal imaging + core cuts confirm substrate suitability.

- Secure three itemized bids using the worksheet; insist on CRRC‑listed products and 20‑mil minimum spec.

- Apply for LADWP cool‑roof rebate early—funding cycles can close mid‑fiscal year.

- Target installation between May–October; lock dates now to avoid contractor backlog.

- Schedule first post‑wash six months after cure; set recurring annual inspections to maintain warranty.

Ready to Extend Your Flat Roof’s Life?

Talk to Torrance Roofing Masters for a free on‑site assessment and a tailored silicone roof coating plan.

Torrance Roofing Masters3812 Sepulveda Blvd, Torrance, CA 90505