Standing Seam Metal Roof in Southern California: Pros, Cons, Lifespan, Best Uses

Quick SoCal take: Is it worth it here?

The 30-second answer (coastal vs inland)

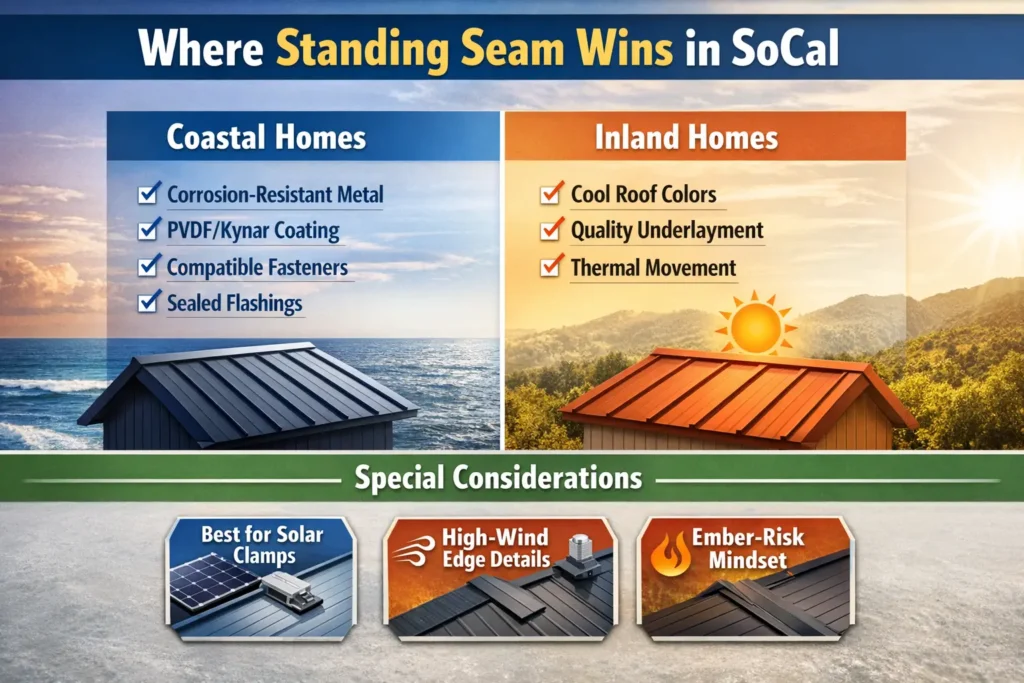

If you live near the coast, a standing seam metal roof can be a smart long-term move, but only when the system is built for salt air. That means corrosion resistance is the first filter: the right metal choice (often aluminum near the ocean, or properly protected steel), the right coating (PVDF/Kynar is the common “premium coating” benchmark), and the right fasteners and flashing details so you don’t create rust points. Inland, the value case shifts. Heat waves and strong UV put the finish, underlayment, and thermal movement details front-and-center. Installed correctly, standing seam is one of the lowest-maintenance roof systems you can put on a home in SoCal.

Who should seriously consider it (and who shouldn’t)

Strong fit: coastal homes, modern architecture, homeowners who want durability, and anyone planning PV solar (standing seam panels can accept clamp-mounted hardware with fewer penetrations). Not ideal: very tight budgets, extremely cut-up roof geometry with lots of transitions, or owners expecting “perfectly flat” panels with zero visual waviness.

What this guide covers (Torrance + wider SoCal conditions)

This guide breaks down pros and cons tied to Southern California realities: coastal salt and marine layer moisture, inland heat and UV, Santa Ana wind exposure, occasional inland hail dents, wildfire ember risk, and what to look for in the roof system, coating, and installation details before you buy.

What a standing seam metal roof is (and what it isn’t)

Standing seam metal roofing basics (panels, seams, clips)

Standing seam metal roofing uses long metal panels that lock together with raised seams. Those seams sit above the water line, which is the whole point. The panels don’t rely on exposed screws across the face to stay watertight. Instead, a clip system anchors each panel to the roof deck, then the next panel covers and locks over it. That hidden-attachment approach is why a properly built standing seam system handles wind-driven rain better than many “screw-down” metal roofs. Panel gauge matters because it affects strength, oil-canning tendency, and how the system behaves over time. It’s not just “thicker is always better,” but the gauge should match the roof design, spans, and exposure.

Snap-lock vs mechanical seam (where each fits in SoCal)

Snap-lock panels click together. Mechanical seam panels are crimped (often in one or two steps) for a tighter lock. In higher exposure areas such as wind-prone ridgelines or coastal zones where details matter more, mechanical seam is often the safer choice because the seam lock is more resistant to uplift and water intrusion.

Standing seam vs corrugated metal roof (through-fastened)

Corrugated or ribbed metal roofs usually use through-fastened screws with washers. Screws and washers are wear items. They can loosen, back out, or degrade, especially with heat cycling. Standing seam hides fasteners, which reduces those common leak points.

Standing seam vs shingles (asphalt shingles) in coastal + heat zones

Asphalt shingles are familiar and often lower cost up front, but they’re more vulnerable to UV aging and wind damage compared with a well-designed standing seam system. In coastal areas, the metal roof’s corrosion strategy matters; inland, the finish and underlayment choices do the heavy lifting for long-term performance.

SoCal reality check: climate and site factors that change everything

Coastal salt air and marine layer moisture: corrosion and detailing priorities

Near the ocean, “metal roof in coastal areas” really means “how well is the whole system protected from salt.” Salt air is corrosive, and the damage usually starts at cut edges, scratches, and dissimilar-metal contact points, then shows up as rust staining or fastener corrosion. Coastal success comes from picking the right metal and pairing it with a high-quality coating, then keeping water out of seams and transitions with clean flashing details.

Inland heat waves and intense UV: coatings, colors, and thermal movement

Inland valleys bake. UV and heat punish cheap finishes, so the coating choice matters more than most homeowners expect. PVDF (often called Kynar) is the finish you’ll see specified when color stability is a priority. Heat also drives thermal movement, so panels, clips, and details need room to expand and contract without buckling or tearing at fasteners.

Santa Ana winds + uplift: edge metal, clip spacing, fastening strategy

A high-wind metal roof isn’t just “strong panels.” Uplift forces attack the perimeter first. Edge metal, proper fastening strategy, and correct clip spacing are what keep the system tight when gusts hit, especially at eaves, rakes, and ridgelines.

Occasional inland hail dents: what dents, what doesn’t, and why it matters

Hail dents are usually cosmetic, not a leak by themselves. Thicker gauge panels resist denting better, but even then, the finish can show impact marks depending on the profile and substrate support.

Wildfire ember exposure: roof assembly mindset (Class A, vents, debris)

In wildfire-prone areas, the roof is only one piece of the puzzle. Class A performance, ember-resistant vents, and keeping valleys and gutters clear of debris matter because embers look for pockets where they can sit and smolder.

Code and compliance in California: what’s statewide vs what varies locally

Title 24 cool roof considerations + CRRC-rated products (high level)

In California, roof work can trigger energy-related requirements, and Title 24 is the big statewide framework people hear about. For homeowners, the practical takeaway is this: roof color and coating performance may matter, especially when you’re replacing a roof (not just patching it). Many metal roofing products are offered in “cool roof” finishes, and CRRC-rated products make it easier to document reflectance/emittance when it’s required. The exact trigger points and what counts can depend on the scope of work and local enforcement, so treat this as a planning checkpoint, not a universal rule.

Permitting realities (reroof vs tear-off, sheathing repairs, inspection steps)

Most full reroofs require permits. Whether you can overlay or must tear off, how many layers are allowed, and when deck (sheathing) repairs require inspection can vary by city/county and sometimes by HOA rules. A good contractor will flag these early because they affect cost, schedule, and the roof assembly details.

Wildland-Urban Interface (WUI) and ember-resistance considerations (where applicable)

Some neighborhoods fall under WUI requirements. That can influence the broader assembly: how edges are detailed, how vents are handled, and how you reduce ember entry points. It’s not just “pick a Class A roof.”

Wind exposure notes (coastal/inland corridors) and manufacturer uplift ratings

Wind design isn’t one-size-fits-all across SoCal. Coastal and inland corridors can see very different pressures. This is where manufacturer uplift ratings and tested systems matter, along with correct clip and fastener patterns to match the approved assembly.

Contractor-grade system choices that matter in SoCal

Panel gauge and metal type (steel vs aluminum vs zinc vs copper)

Homeowners often fixate on one number (gauge), but it’s really a combo of metal type, thickness, profile, and how the roof is attached. Steel panels are common because they’re strong and cost-effective, but in corrosive coastal conditions the protection strategy has to be right. Aluminum costs more, yet it’s naturally more forgiving around salt air because it doesn’t rust the way steel does. Zinc and copper are specialty options. They can last a long time and develop a natural patina, but they’re not a “set it and forget it” choice for every home. Details, compatibility with other metals, and where water runs matter a lot.

Coastal recommendation logic (aluminum/finish strategy)

Near the coast, the job is to reduce corrosion pathways. Aluminum panels paired with a premium coating (often PVDF/Kynar) can be a strong play, especially when you’re close enough to taste salt in the air. The catch: aluminum still needs correct flashing and fasteners, and you want clean separation from dissimilar metals so you don’t create corrosion at contact points.

Natural patina metals (zinc/copper): where they shine and where they don’t

Zinc and standing seam copper look great on the right architecture. They also come with real-world constraints: higher material costs, more sensitive detailing at transitions, and more room for installation errors if the crew doesn’t work with them regularly.

Coatings/finishes: PVDF (Kynar) vs SMP (fade/chalk expectations)

In the SoCal sun, finish quality shows up fast. PVDF/Kynar is typically chosen for better long-term color stability and chalk resistance. SMP can work, but you should go in with realistic expectations about fading and chalking over years of UV.

Underlayment choices for heat + moisture (and why it changes performance)

Underlayment is the backup waterproofing layer under the sheet metal panels. In marine layer zones and hot inland attics, the right underlayment helps manage heat, minor condensation events, and wind-driven rain at tricky flashing points.

Ventilation approach (when it helps, when it’s a red herring)

Ventilation matters when the attic assembly needs it, but it won’t “fix” a bad roof design. Good venting supports temperature and moisture control. It doesn’t replace proper panel layout, flashing, or corrosion resistance.

Standing seam clips vs fasteners: floating clips, spacing, thermal expansion

A standing seam system lives and dies by attachment details. Floating clips allow thermal expansion without ripping at fasteners or distorting seams. Clip spacing is not guesswork; it’s tied to wind exposure and the manufacturer’s tested assembly. This is where pros pay attention to inches, edge zones, and flashing transitions because that’s where failures start.

Details that prevent leaks: what a pro checks on real jobs

A standing seam metal roof can look perfect from the street and still have leak risk if the details were rushed. During a roof inspection, we spend more time on transitions than on the big open field of panels, because that’s where water finds shortcuts.

Penetrations (pipes, vents, skylights): boots, curbs, and metal compatibility

Penetrations need the right flashing strategy for metal. Pipe boots and skylight curbs have to match panel movement and stay compatible with the roof material. If the boot relies on a sealant bead as the “main waterproofing,” it’s usually a short-term fix, not a long-term detail. We also check for dissimilar metals at vents, plumbing stacks, and fastener heads, because that’s where corrosion can start.

Eaves/rakes and edge metal (wind-driven rain + uplift)

Edges take the beating in SoCal wind events. Proper edge metal isn’t cosmetic. It controls uplift, keeps water from being pushed back under the panel line, and protects the assembly at the perimeter.

Valleys and transitions (dead valleys, diverters, water control)

Valleys concentrate water, leaves, and grit. “Dead valleys” and awkward transitions are common failure zones, so we look for diverters, clean water channels, and flashing that doesn’t trap debris against seams.

Chimney and wall transitions (counterflashing logic)

Chimneys and walls need step flashing and counterflashing that shed water in layers. If water can run behind the counterflashing, it will.

Dissimilar metals + galvanic corrosion: where problems start

Galvanic corrosion is avoidable, but only if someone is thinking ahead. Mixing metals without separation, or using the wrong fasteners, creates a slow leak you don’t see until staining or rust shows up. Roof safety matters here too, because checking these areas properly requires safe access and a careful roof condition assessment.

Pros and cons (SoCal-specific, not generic)

Pros in Southern California (coastal + inland benefits)

Here’s the real value of standing seam metal roof pros and cons in SoCal: the upside isn’t just “metal lasts long.” It’s how the system handles our mix of sun, wind, and coastal exposure. Inland, a high-quality finish holds up better under intense UV, and the panels shed heat well when you choose the right coating and color. In wind-prone areas, a properly engineered standing seam system has serious strength because the fasteners are protected and the seams are built to stay locked. Along the coast, corrosion resistance can be excellent when the metal type, coating, and flashing details are chosen for salt air. For many homeowners, the “little maintenance” angle is real too. You’re not chasing brittle tabs or granule loss like you might with asphalt shingles.

Cons and trade-offs (what homeowners should expect)

The biggest trade-off is cost and complexity. Standing seam is a system, not just a material, and it demands experienced installation. Roofs with lots of hips, valleys, skylights, and chimneys drive labor and flashing time up fast. Also, if you’re expecting a perfectly flat, furniture-grade surface, metal will surprise you.

Noise: what’s myth vs what’s real (and what actually reduces it)

Noise complaints usually come from poorly built assemblies. A solid deck, quality underlayment, and proper attic insulation do most of the sound control. On a typical home, rain “drum” is usually far less dramatic than people fear.

Oil-canning: expectations, causes, and how pros minimize it

Oil-canning is a visual waviness in flat areas of a panel. It’s not a leak and it’s not a structural failure. It’s driven by panel width, gauge, handling, thermal movement, and how the roof was laid out. Pros minimize it with smart panel selection, correct clip strategy, careful loading/handling, and clean alignment so the roof’s appearance matches the quality you paid for.

Best-use decision guide for SoCal homes

Coastal homes: salt air metal roofing “best practices” checklist

If you’re near the coast, treat salt as the main design load. Quick checklist: pick a metal and coating built for corrosion resistance, avoid mixed metals at flashings, use compatible fasteners, and keep cut edges protected. Ask how valleys, eaves, and roof-to-wall transitions are detailed, because those are the zones that stay damp longer under the marine layer.

Inland heat: cool-roof colors + comfort/energy angle

Inland, your roof is basically a heat shield. Standing seam metal roof colors matter here. Lighter “cool roof” finishes can reduce heat gain, and quality coatings stay stable under UV. Dark colors can still work, but they lean harder on attic insulation, ventilation, and the right underlayment to keep comfort where it belongs: inside the house.

High-wind zones: uplift-rated assemblies + edge details

For Santa Ana corridors and exposed ridgelines, focus on the tested assembly, not just the panel. A metal roof standing seam system needs the right clip spacing, perimeter fastening, and edge metal so uplift forces don’t peel the roof from the outside in.

Wildfire-prone areas: ember resistance mindset (roof + vents + gutters)

A roof alone doesn’t stop embers. The best results come from a full assembly mindset: Class A roof design, ember-resistant vents, clean valleys, and gutters that don’t hold dry debris.

Modern architecture + HOA constraints (standing seam metal roof colors)

Standing seam fits modern lines, but HOA rules can narrow the palette. If you want a black standing seam metal roof, confirm approved color families early and choose a finish known for holding color well in sun.

Solar plans: PV solar on standing seam (clamps vs penetrations)

Solar is one of the clearest “yes” cases. Many PV solar on standing seam installs use clamp-mounted hardware attached to the seams, which can reduce penetrations. The key is coordination: roof layout, array placement, and flashing strategy should be planned together so warranties and water control stay intact.

When standing seam is NOT the best fit

Standing seam is a great system, but it’s not the answer for every roof. Being honest here saves you money and headaches later.

Complex roof geometry and heavy flashing count (labor + leak risk)

If your roof has a lot of hips, valleys, dormers, skylights, and chimneys, the installation becomes a flashing job more than a panel job. That increases labor, raises prices, and adds more transition points where water control has to be perfect. A simpler system may perform just as well for less cost on highly cut-up roofs.

Budget constraints and “value engineering” options

Standing seam can be a high upfront spend. If your budget is tight, “value engineering” might mean choosing a different metal roofing profile, selecting a different coating level, or even comparing asphalt shingles plus targeted upgrades (better ventilation, improved underlayment, stronger edge details). The goal is a roof system that fits your finances without creating future maintenance problems.

Low-slope limitations (and when a different system is smarter)

Some homes have low-slope sections where water moves slowly. Standing seam can work in certain designs, but slope, seam type, and details become critical. In some cases, a different low-slope roofing system is simply the smarter, more watertight choice.

Heavy shade/debris zones: what increases maintenance in SoCal

If your roof sits under trees or collects leaf litter in valleys, you’ll have more maintenance no matter what material you choose. Debris holds moisture, wears coatings faster, and can force water to back up at transitions. If you want “set it and forget it,” this site condition matters as much as the roof itself.

Lifespan in SoCal + maintenance you can actually follow

Standing seam metal roof lifespan: coastal vs inland ranges (realistic)

In Southern California, lifespan isn’t one number. Inland roofs usually have an easier life: less salt, less constant moisture, and fewer corrosion triggers. Along the coast, the system can still last for decades, but the margin for error is smaller. Corrosion resistance comes from the full package: metal type, coating quality, flashing compatibility, and clean fastener choices. If any of those are weak, the roof can look “aged” early even if it isn’t leaking yet.

What shortens lifespan fastest (salt, wrong fasteners, scratches, debris)

The big roof killers here are preventable: salt exposure without the right detailing, wrong fasteners or mixed metals that start galvanic corrosion, scratches left unprotected, and debris that traps moisture in valleys and against seams. Sealants matter too. A roof that depends on exposed sealant as the main waterproofing usually needs more frequent touch-ups.

Maintenance checklist (homeowner-friendly)

- Keep valleys, gutters, and roof-to-wall transitions free of leaves and grit

- After heavy wind, check for lifted trim, loose edge metal, or bent flashing

- Look for early warning signs: rust staining, coating wear, backed-out fasteners, or opened seams

- Schedule a professional roof inspection if you see water marks inside or suspect movement at penetrations

Inspection cadence (after wind events, annually, and after solar work)

Plan on an annual check, plus a quick look after Santa Ana wind events and any time solar work is done on the roof.

Coating touch-ups and scratch protocol

Treat scratches quickly. Clean, dry, and use the manufacturer-approved touch-up method so bare metal isn’t exposed to salt air.

Repairability: panel replacement realities and what’s “fixable”

Small issues at flashings and penetrations are often fixable without replacing whole panels. True panel replacement can be more involved because panels interlock. That’s why correct original installation and careful roof maintenance pay off for years.

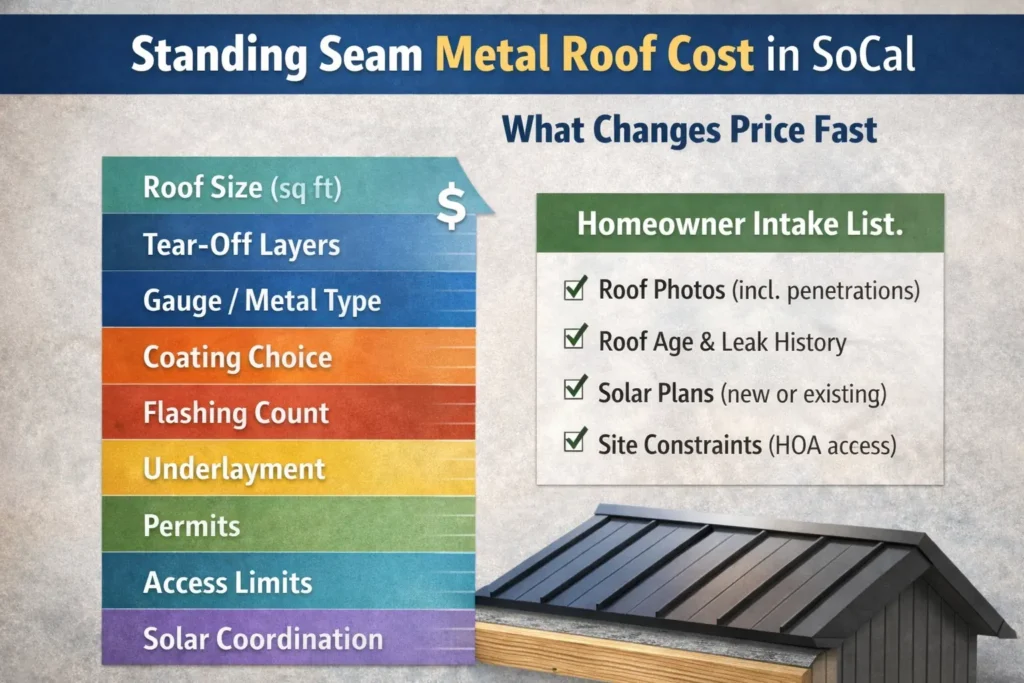

Standing seam metal roof cost in SoCal (what drives it)

When people ask about standing seam metal roof cost, the honest answer is: the roof design and the assembly details usually move the price more than the “metal” itself. You’re paying for a system, skilled labor, and the parts that keep water out for years.

Pricing drivers that change fast (10–15 item list)

Here are the factors that swing standing seam metal roof price quickly in Southern California:

- Roof size (total square foot and how it breaks into sections)

- Roof pitch and how safe/complex access is

- Tear-off vs overlay, and number of existing layers

- Deck condition (sheathing repairs, rot, uneven framing)

- Panel profile and seam type (snap-lock vs mechanical seam)

- Panel gauge and metal type (steel vs aluminum vs specialty metals)

- Coating/finish level (material costs vary a lot here)

- Underlayment choice and any high-heat/waterproofing upgrades

- Amount of flashing work (valleys, dormers, chimneys, skylights, walls)

- Edge metal scope (eaves/rakes) and wind-exposure detailing

- Ventilation upgrades (intake/exhaust corrections)

- Permits, inspections, and jobsite requirements

- Disposal fees and access constraints (tight driveways, landscaping protection)

- Solar integration (planning, mounts, coordination with trades)

- Lead times and color availability for standing seam metal roof panels

Standing seam metal roof cost vs shingles vs corrugated (value comparison)

Asphalt shingles usually win on upfront cost. Corrugated/through-fastened metal often sits in the middle. Standing seam is typically the premium option because the hidden-clip system, long panels, and detailed flashing work take more labor. The value case is long service life, fewer exposed fastener leak points, and better performance in wind and sun when the assembly is built correctly.

What to gather for an accurate estimate (homeowner intake list)

To get a real number (not a guess), have: roof age, known leak areas, photos of the roof planes and penetrations, attic notes (venting/insulation), any prior repairs, your preferred color/finish, and whether you’re planning solar.

Light commercial/multi-family overlap (large-roof drivers + permitting notes)

Bigger roofs shift the math. Material costs per square can improve, but labor planning, staging, safety requirements, and permitting coordination can add complexity. Low-slope sections and rooftop equipment also increase flashing scope, which is often the real driver on larger systems.

How Torrance Roofing Masters approaches standing seam installs

Our process (inspection → design → installation → final walkthrough)

We start with a roof inspection that looks beyond “is it leaking.” We document roof planes, penetrations, valleys, chimney transitions, and edge conditions, then confirm deck health and ventilation basics. From there, we map the roof design around water flow and thermal movement, not just panel layout. During roof installation, we focus on sequencing: underlayment first, then edges and flashings, then panels and seams, then final trim and penetrations so nothing is forced or “made to fit” at the end. The final walkthrough is where we verify details, answer questions, and show you what to watch for going forward.

Quality assurance points (what we measure/verify)

Quality assurance is practical, not theoretical. We verify panel alignment, seam engagement, clip and fastener placement per the selected system, clean flashing transitions at penetrations, and tight edge metal where wind-driven rain shows up first. We also check for avoidable issues like dissimilar metal contact and unprotected cut edges.

Safety and professionalism (crew practices + jobsite protection)

Our crews follow roof safety practices that protect your home and our installers. That includes fall protection where required, controlled material staging, and jobsite protection for landscaping and access paths. Practical experience matters here: clean work and safe workflow reduce mistakes that can shorten a roof’s life.

FAQs: SoCal homeowner questions

Next steps: get a SoCal standing seam quote (CTA)

If you’re considering standing seam metal roofing, the fastest way to get a useful estimate is to share a few specifics upfront.

What we need from you

- Photos of each roof plane (and close-ups of valleys, skylights, chimneys, and vents)

- Approximate roof age and any known leak history

- Whether you want a specific finish or standing seam metal roof colors

- Solar plans (new PV, existing PV, or “maybe later”)

- Any HOA constraints or access limitations

Book an inspection / request a quote

Ready for real numbers on roof cost, not guesses? Request a roof inspection and we’ll walk you through options, pricing drivers, and the roof assembly details that matter in Southern California.

Contact us here: https://torranceroofingmasters.com/contact/